City Water Plant Upgrades 200 Electromagnetic Flow Transmitters for Better Accuracy

Aug. 19, 2025

Introduction

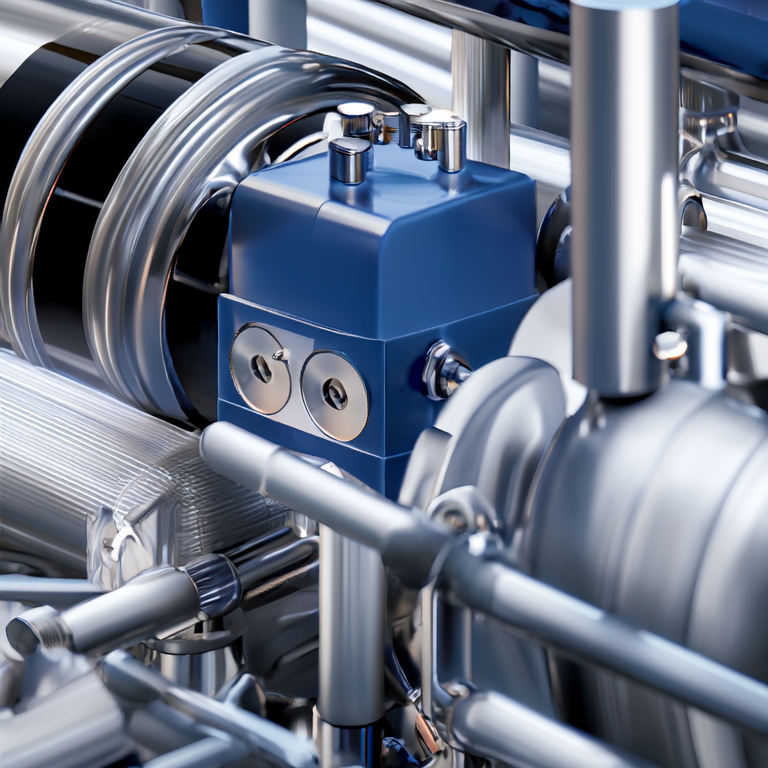

The city water plant has recently adopted 200 electromagnetic flow transmitters to improve accuracy. Flow measurement accuracy is crucial for efficient water management. Inaccurate flow measurement can lead to inefficient operations, wasted resources, and higher costs. The integration of advanced flow measurement technology helps in ensuring accurate water delivery, reducing maintenance concerns, and enhancing overall system reliability. This upgrade will positively impact water distribution and management.

Summary Answer

The upgrade of 200 electromagnetic flow transmitters significantly enhances measurement accuracy and reliability in water distribution systems.

Benefits of Electromagnetic Flow Transmitters

High Accuracy

Electromagnetic flow transmitters provide measurement accuracy of ±0.2%. This is crucial for billing and regulatory compliance.

Low Maintenance

With no moving parts, these transmitters require less maintenance than traditional flow meters. This leads to reduced downtime.

Wide Application Range

These devices work with various fluids, including clean water and wastewater. This versatility makes them suitable for different applications.

Reduced Pressure Loss

Electromagnetic flow meters do not slow down flow, helping maintain system efficiency and reducing energy costs.

Real-Time Data Monitoring

They offer real-time monitoring and data collection. This helps operators make informed decisions quickly, enhancing operational efficiency.

Environmental Benefits

Accurate flow measurement contributes to better water resource management. This supports sustainable practices and environmental conservation.

Conclusion

In summary, the city\'s upgrade to 200 electromagnetic flow transmitters marks a significant improvement in flow measurement accuracy. This project enhances the efficiency of the water distribution system and supports better resource management. The benefits of these advanced devices ultimately lead to a more reliable and efficient city water plant.

FAQ

1. What is an electromagnetic flow transmitter? It\'s a device that measures the flow rate of electrically conductive fluids using electromagnetic principles.

2. How do electromagnetic flow transmitters work? They measure flow by applying a magnetic field and recording the voltage created by the flowing fluid.

3. Do these devices work with all types of fluids? They can work effectively with conductive fluids, making them suitable for many industrial applications.

4. Why are they better than traditional flow meters? Their high accuracy, low maintenance, and real-time capabilities make them superior for many applications.

5. What are the cost implications of upgrading to these transmitters? Though the initial investment might be higher, the long-term savings from accuracy and reduced maintenance costs often outweigh it.