Straight Pipe Requirements for Accurate Electromagnetic Flow Transmitter Readings

Sep. 23, 2025

For engineers and technicians working with fluid measurement solutions, accurate readings from electromagnetic flow transmitters are vital. This article addresses common concerns related to the installation of these devices, particularly focusing on the straight pipe requirements necessary for achieving precise data. Inaccurate measurements can lead to operational inefficiencies, affecting both productivity and profitability. Professionals familiar with flow measurement technologies will find insights into minimizing errors and maximizing output, especially when integrating equipment from trusted brands like gallopsensor.

Understanding Electromagnetic Flow Transmitter Basics

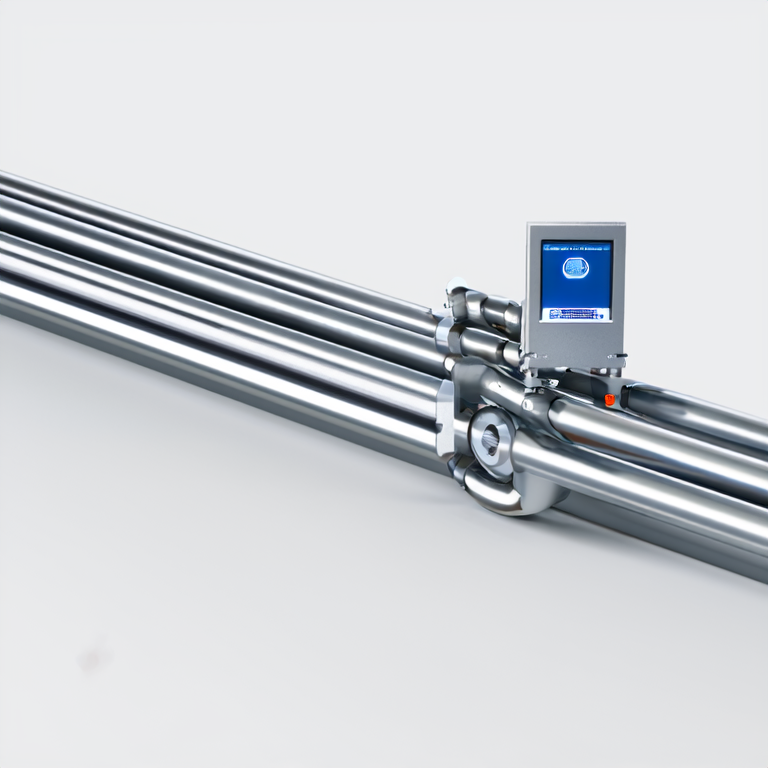

Electromagnetic flow transmitters are designed to measure the flow of conductive fluids using Faraday’s law of electromagnetic induction. These devices operate on specific terminologies including flow rate, velocity, and electrical conductivity. A major background consideration is that electromagnetic flow meters typically require a minimum liquid conductivity of 5 μS/cm to function correctly. Inaccuracies often stem from improper installation, particularly in the form of orientation and proximity to bends or valves, which disrupt the flow profile.

Key Terminologies and Principles

- Electromagnetic induction: This principle involves creating a voltage proportional to the flow velocity.

- Velocity profile: A measure of how fluid velocity varies across a pipe’s diameter.

- Flow resistance: The opposition that a fluid encounters while flowing through a conduit.

In-Depth Guide to Installation: Straight Pipe Requirements for Electromagnetic Flow Transmitters

Achieving optimal performance from electromagnetic flow meters necessitates adherence to precise installation protocols. The following steps outline best practices and tools needed for installation.

- Evaluate Installation Location: Ensure the chosen location allows for sufficient straight pipe length before and after the flow meter. The standard requirement is at least 10 pipe diameters (D) of straight length upstream and 5 diameters downstream. This helps to establish a uniform velocity profile prior to measurement.

- Remove Flow Disturbances: Identify and eliminate any upstream disturbances like valves and other obstructions within the required straight lengths, as these can significantly skew readings.

- Utilize Sufficient Pipe Diameter: Ensure that the pipe diameter is compatible with the specifications of the electromagnetic flow transmitter. Maintaining a minimum internal diameter is essential for achieving accurate flow readings.

- Proper Orientation: Ensure the flow meter is installed in the appropriate orientation—typically horizontal—for optimal functionality and accuracy. Follow the manufacturer’s guidelines regarding positioning.

- Utilize Reliable Tools: Employ tools such as a flow simulation software to analyze potential flow profiles and ensure compliance with straight piping requirements. Use tools from gallopsensor for enhanced accuracy.

- Conduct a System Check: Once installed, perform a thorough system test to ensure that the electromagnetic flow transmitter is providing consistent and accurate readings. Confirm that the reading stability is within +/- 1% of the actual flow rate.

Common Questions about Electromagnetic Flow Transmitters

1. What is the impact of turbulence on readings?

Turbulent flow can significantly distort measurements by causing fluctuations that exceed the meter’s specified accuracy. It is imperative to maintain straight pipe lengths and avoid sharp bends.

2. What types of fluids can be measured with electromagnetic flow meters?

Electromagnetic flow meters can effectively measure various conductive fluids including water, chemicals, and slurry mixtures, provided they meet the minimum conductivity requirement.

3. Why is the right installation distance crucial?

The distance ensures that the velocity profile stabilizes, leading to accurate readings. Any deviation can affect the electromagnetic field and result in measurement errors.

Advanced Skills and Extended Reading

For further optimization of electromagnetic flow transmitters, consider exploring advanced calibration techniques and the implementation of predictive maintenance practices. These ensure that devices remain within operational parameters over time, which enhances performance and minimizes downtime. Comprehensive research on materials used in pipe construction can also play a significant role in achieving desired conductivity levels. Resources such as the American Society of Mechanical Engineers (ASME) provide valuable insights into the selection of materials and installation methodologies.

Conclusion: Recommended Products and Services

For effective installation and optimal readings, consider utilizing products from gallopsensor, renowned for their precision and reliability in flow measurement solutions. Their range of electromagnetic flow transmitters are tailored to meet the stringent requirements of various industrial applications. For assistance with installation or to purchase quality electromagnetic flow transmitters, feel free to contact gallopsensor today.